The monitoring of a well is needed to:

- look at the reservoirs dynamics and to optimize their production (flow profiling)

- provide a quick and efficient response to the failures observed on the completion parts, the tubings/casings and detect leaks

- monitor operations such as stimulation or hydraulic fracturation

- monitor the levels of the products stored in salt caverns or geological reservoirs.

Our patented technology of distributed fiber optic sensing offers major advantages over traditional methods.

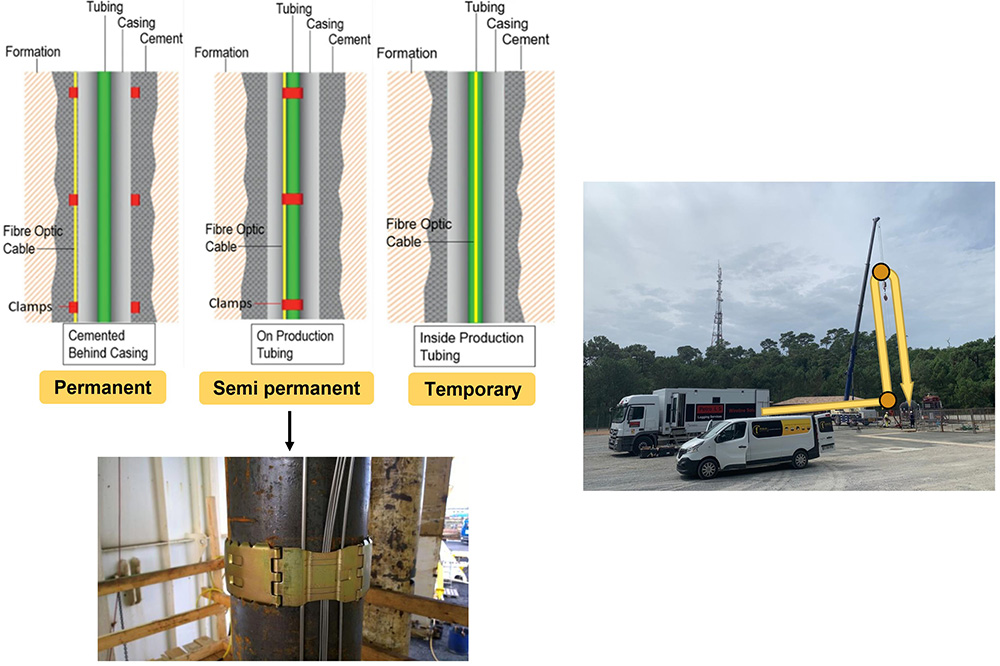

The Sensor Lines interrogators have been developed and optimized to meet all the challenges of well monitoring and its many applications. Our embedded Softwares (on our DAS, DTS, DSS) provide all the tools required to the data processing and are easily implemented in any third-party solutions (hardware or software implementation). The fiber optic cable can be permanently deployed during the well completion or temporarily via wireline or slickline.

Permanent, semi permanent or temporary installation of the optical fiber by our partners

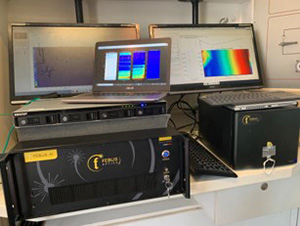

On the left, the Sensor Lines A1 (DAS) and on the right the Sensor Lines ,T1-R (DTS) in the control room

for a real-time monitoring

The fiber optic sensing is a non-intrusive method that allows to optimize the monitoring and maintenance costs of the well. It also provides:

- acoustic information with the Sensor Lines A1 (DAS – Distributed Acoustic Sensing) like the “Noise Logging Tool”

- temperature data with the Sensor Lines T1-R (DTS – Distributed Temperature Sensing)

- strain information with the Sensor Lines G1-R (DSTS – Distributed Strain and Temperature Sensing)

Distributed, continuous and real-time data are obtained along the well.

The gauge length is also adaptable before and after the operation on the Sensor Lines A1 (DAS – Distributed Acoustic Sensing).